Anti-Corrosion – Coating

Anti-Corrosion

In the ground

Corrosion allowance of 1mm is generally taken into account, when they are free from acid, salt or harmful industrial waste water according to the specification “Japan Road Association: Specification for Highway Bridges, Part Ⅳ Substructures, 2002.3”.

This is based on a lot of data of test steel members buried in the ground and real steel sheet piles driven underground for long time up to 33 years.

When they are influenced by acid, salt or harmful industrial waste water, they should be protected from corrosion by coating or cathodic protection.

In the sea

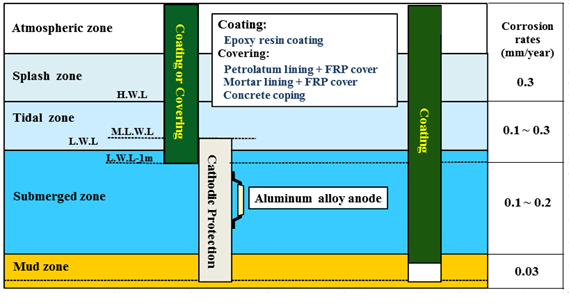

The degree of corrosion of steel materials varies greatly in the depth direction as shown in the figure according to the standard “The Ports and Harbor Association of Japan: Technical Standards and Commentaries for Port and Harbor Facilities in Japan, July 2007″.

Design example for epoxy coating

| Type | ISO 12944 Paint systems for low alloy carbon steel for corrosivity category C4 | Characteristic | |||||||

| Corrosivity Category: lm1, lm2, lm3 | Coating system | Expected Durability in year *2 | Anti-corrosive | Anti-abrasion | |||||

| System No. | Generic type | No. of Coats | Total NDFT (μm) | Low 2-5 |

Medium5-15 | High >15 | |||

| Polyurethane | – | Polyurethane | 1 | 2000 | ◎ most High |

– | |||

| Epoxy *1 | A6.06 | High-build Epoxy | 2 | 800 | ◎ very High |

– | |||

| A6.04 | Epoxy + Glass Flake Epoxy | 3 | 500 | ○ High |

◎ | ||||

| A6.10 | Epoxy | 2-3 | 600 | ○ High |

– | ||||

| A6.09 | Epoxy | 1 | 400 | △ Medium |

– | ||||

| – *No mention |

Zinc Phosphate Epoxy | 1 | 50-75 | Temporary protection | – | ||||

*1 This paint system complies with immersion categories lm1, lm2 and lm3 in ISO 12944 Paint systems for low alloy carbon steel

*2 Durability is supposition, not guaranteed

- Anti-corrosion coated pipe

- Heavy Duty Coated [NS-PAC]

- Coating process

- Inspection process

Please don’t hesitate to contact us for further detail