HAT H Steel Sheet Piles

Hat-type and H-shape combined high stiffness steel sheet piles

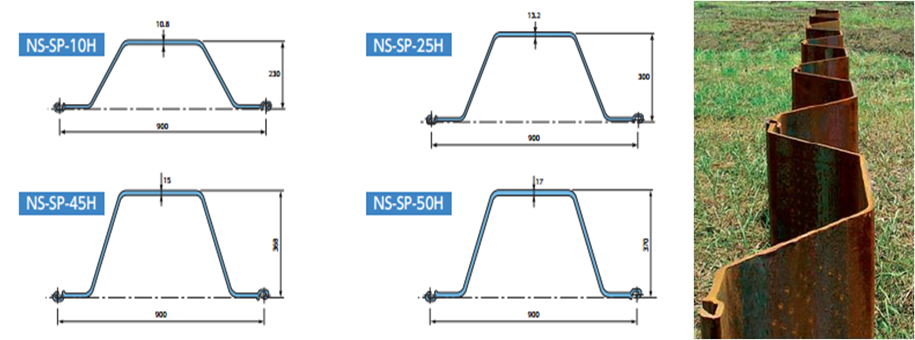

Shape (*)

Hat-type and H-shape combined high stiffness steel sheet piles come in combination of Hat-type sheet piles which have four types and H-shape sections which have many types and can be welded together at NPV factory by skilled workers.

Hat-type sheet pile (*)

Effective width 900mm

Effective width 900mm

Produced by NPV

Fillet weld: Welding ratio: 40-60% (*)

Applications

- River Revetment

- Temporary retaining wall

- Quay wall

Features

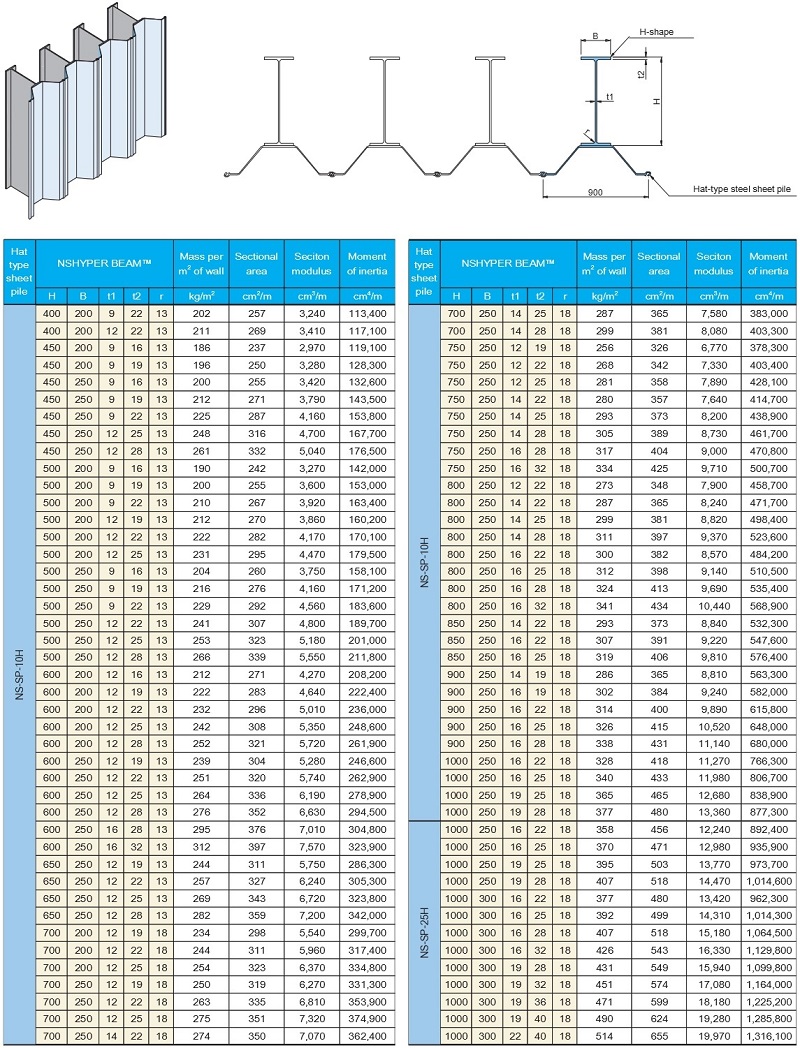

Availability of numerous sectional properties

Hat-type and H-shape combined high stiffness steel sheet piles come in combination of Hat-type sheet piles which have four types and H-shape sections which have many types. Eventually they provide more than 200 types of economical properties. (Section modulus per meter of wall: Approx.2,320 to 19,970 cm3/m)

Ease of fabrication

It is easy to fabricate Hat-type and H-shape combined high stiffness steel sheet piles by combining Hat-type and H-shape with intermittent fillet welding.

Excellent cost-effectiveness

From the viewpoint of design for the Hat-type and H-shape combined high stiffness steel sheet pile, Hat-type functions as a continuous wall to sustain soil and water, and H-shape functions as a structural member to bear the bending moment. This makes it possible to use low-cost H-shape up to 50 to 70% of weight as well as avoiding use of expensive connectors to connect a sheet pile and a section.

Ease of installation

An ordinary vibratory hammer is directly applicable for driving. The Hat-type and H-shape combined high stiffness steel sheet pile, having higher moment of inertia per pile compared with Z-type and other type piles, is very easy to work with.

Sectional properties (*)

– Basic type –

– Alternated type –

(*) Citation: NIPPON STEEL CORPORATION “STEEL SHEET PILES” (K007en_01_201904p)